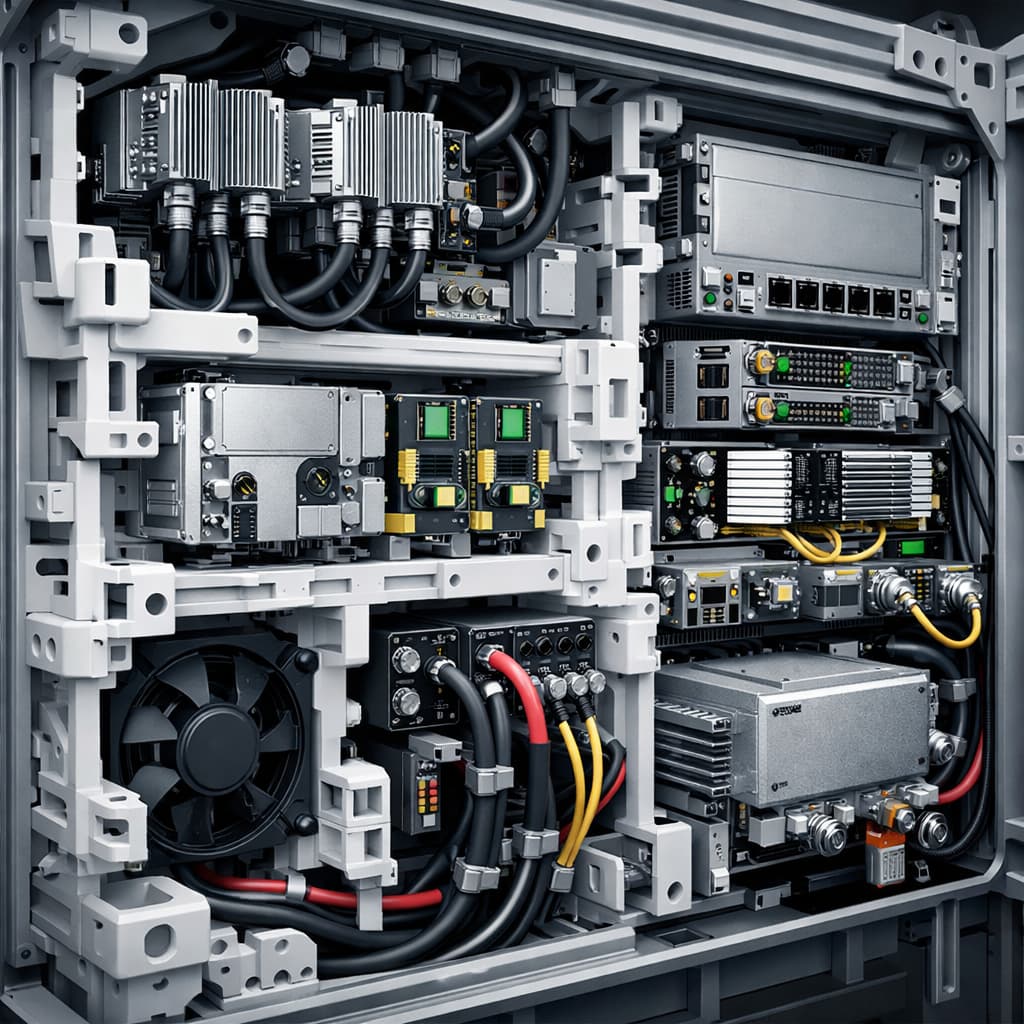

With the rapid deployment of 5G communication technology, significant changes have occurred in operating frequency, power density, and structural integration of communication equipment. Compared with previous generations, 5G devices must support higher data rates and lower latency while integrating multiple antennas, high-frequency circuits, and thermal management systems within increasingly compact spaces. Under these conditions, the electrical stability of materials has become a critical factor in overall system reliability, driving growing interest in high-CTI nylon materials.

In communication equipment, CTI (Comparative Tracking Index) is a key indicator used to evaluate the resistance of insulating materials to surface tracking and electrical leakage under humid or contaminated conditions. As power density and voltage gradients increase in 5G systems, insufficient surface insulation performance may lead to arcing, carbonized tracking paths, and eventual electrical failure during long-term operation. High-CTI nylon materials provide enhanced safety margins through targeted molecular and formulation design.

From a material mechanism perspective, high-CTI nylon typically reduces surface polarity, optimizes filler systems, and minimizes ionic impurities to suppress the formation of conductive tracking paths. Compared with conventional reinforced nylons, these materials maintain insulation integrity for extended periods even under moisture and pollution exposure. This characteristic is particularly critical for outdoor base stations, power supply modules, and high-density connectors.

In high-frequency applications, dielectric properties are equally important. High-frequency signals are sensitive to variations in dielectric constant and dielectric loss, which can result in signal attenuation, crosstalk, or phase distortion. High-CTI nylon achieves stable dielectric behavior by optimizing polymer matrix structure and filler dispersion while maintaining superior tracking resistance, ensuring consistent signal performance in antennas, RF module housings, and precision structural components.

From a design perspective, high-CTI nylon offers additional advantages over metallic materials, including excellent electrical insulation, reduced weight, and enhanced design flexibility. Its dimensional stability and surface quality in injection molding processes support complex geometries and high-precision assemblies, minimizing the impact of manufacturing variations on electrical performance.

Thermal stability is another critical factor, as 5G equipment often operates under continuous heat generation. Through heat-resistant modification and stabilization systems, high-CTI nylon retains its electrical and dielectric properties under long-term thermal aging, making it a reliable choice for power electronics housings and structural components near heat sources.

Overall, high-CTI nylon has become an increasingly important alternative to conventional engineering plastics in 5G communication equipment. Its balanced performance in tracking resistance, high-frequency stability, processability, and cost efficiency supports both high-end applications and large-scale deployment. As 5G technology continues to evolve toward higher frequencies and integration levels, high-CTI nylon will play a critical role in ensuring long-term equipment reliability.