Poliamidas Os poliamidas (PA) são plásticos de engenharia amplamente utilizados, mas seu desempenho frequentemente precisa ser ajustado por meio da mistura com outros polímeros. Devido às diferenças de polaridade, a maioria das misturas à base de PA requer compatibilizantes para garantir morfologia estável e integridade mecânica. Estudos recentes sobre misturas de PA/PP e PA/PC forneceram novos conhecimentos sobre os mecanismos de compatibilização e otimização de materiais.

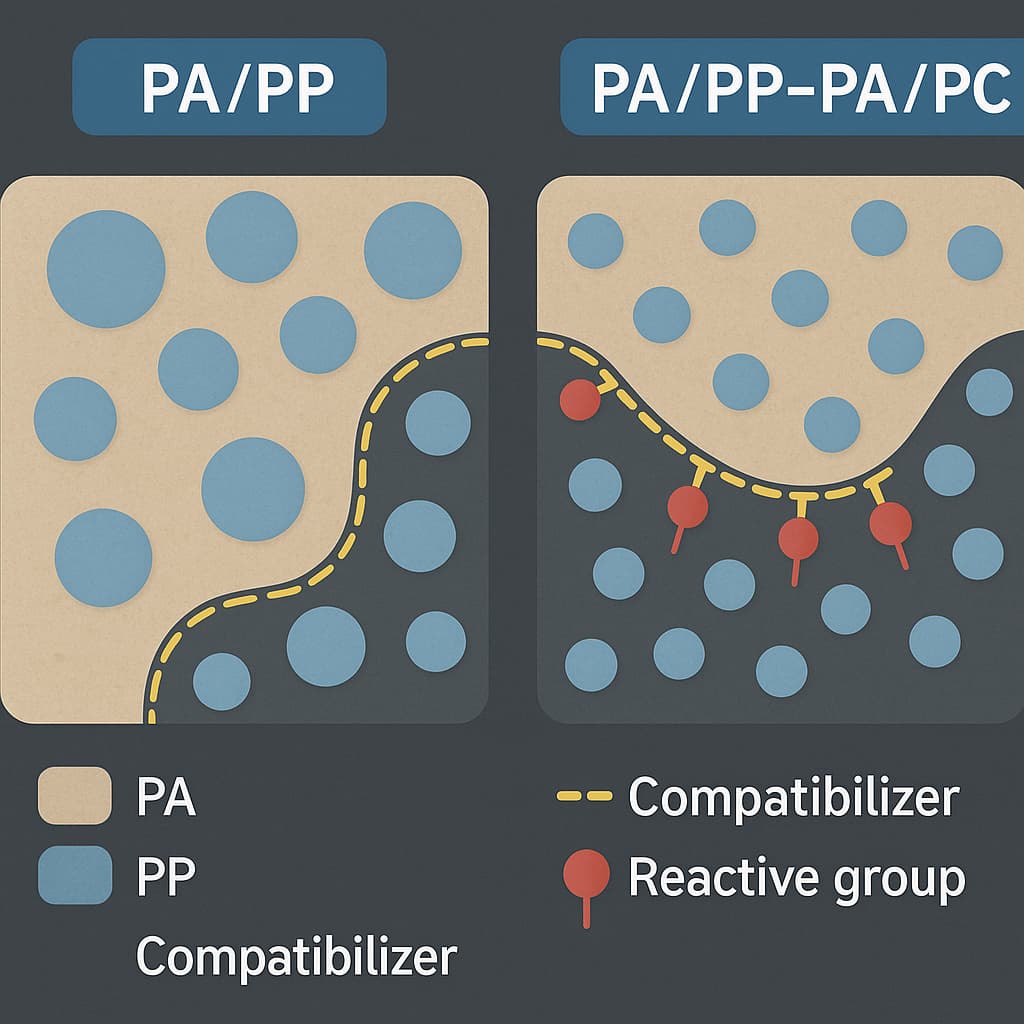

Em misturas de PA/PP, a baixa adesão interfacial causada por grandes diferenças de polaridade leva a uma severa separação de fases. O polipropileno enxertado com anidrido maleico (PP-g-MAH) continua sendo o compatibilizante mais utilizado. Seus grupos anidrido reagem com os grupos amina terminais do PA, formando ligações químicas estáveis que fortalecem a interface. Com pesquisas mais aprofundadas, ficou claro que a eficiência do enxerto, o teor de MAH e a distribuição de massa molecular influenciam significativamente a resistência e a processabilidade finais da mistura.

Os copolímeros em bloco como compatibilizantes representam uma nova direção, permitindo uma dispersão de fase mais fina e maior tenacidade. A compatibilização assistida por nanopartículas também surgiu, melhorando a resistência térmica a longo prazo e o comportamento à fadiga das misturas.

Para misturas de PA/PC, O desafio reside na incompatibilidade das temperaturas de processamento e na complexa química interfacial. Os compatibilizantes funcionais epóxi têm se mostrado altamente eficazes, formando ligações químicas com os grupos terminais de PA e PC. Como resultado, a estabilidade térmica, a resistência ao impacto e a estabilidade dimensional em altas temperaturas foram significativamente aprimoradas.

Os desenvolvimentos recentes focam-se no controlo da taxa de reação, garantindo que a compatibilização ocorre a temperaturas mais baixas para evitar a degradação do PC. Aditivos contendo silício ou segmentos de cadeia flexíveis melhoram ainda mais a transparência, a resistência às intempéries e a durabilidade química.

As estratégias de compatibilidade estão se tornando cada vez mais sofisticadas, permitindo Misturas de nylon para atender aos rigorosos requisitos de aplicações automotivas, elétricas e estruturais.